- Coal

- Mow Cop Colliery

- Engineers Plans

- The Tunnel

- Falls Colliery

- Williamsons

- Rail Track

- Map 1890

- Map ofTramway

- Harriseahead Coal

- Astbury Lime Works

Astbury Limeworks

Before you begin to read this article, you may wish to familiarise yourself with the 1908 map

Lime has been quarried out of this area for at lease 300 years, and some have suggested and with good cause that the Romans quarried lime here. The Romans has a camp nearby in Astbury and a road system that passed very close in several directions, I am also informed that a small Roman lamp was once found in the area of the works. Like modern man the Romans used limestone in it constructions for making mortar and plaster. However it wasn’t until the Industrial Revolution began that these working were put to maximum effect.

There are document at Chester and Cheshire

Archive and Local Study Service, showing accounts as far back as 1708.

The quarry is the leased out several times over the next 200 years

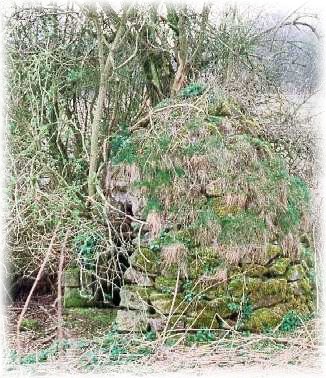

More efficient methods of quarrying were introduced over the years, including blasting. Left is a 17th century powder hut. The limestone was quarried out and taken in large pieces to kilns; on the map these show as recesses in the quarry works. Limestone remains stable up to 800° C and so the kilns would have been fired up and kept running 24 hours a day, the limestone was loaded in layers, first a layer of coal then limestone, and then coal, etc. It was fired and once finished the large lumps of stone were pulled out and water poured over them, this caused slaking which was then turned into paste, to be mixed into plaster or dried to make lime for farmers fields.

17th Century Powder Hut

- Limeworks Video

- Tunnel

Video

The Tunnel is now sealed and is on private property. there is no public access. - In Depth study be Len Kirkham

- Chester Archive List

- Geology

of the area

All the spoil was piled up around the

kilns; that is why we have recesses in the North side of the quarry markings.

As time moved on the quarry got very deep, in fact by 1828 it was 300 ft deep

with over a mile of networked tunnels beneath the surface.

The Kilns were moved further down the road, next to Baytree Farm. A tunnel

was then dug out with 3 airshafts (left & below) along the route,

this then had rails put in and simple carts could then easily move the limestone

to the new works.

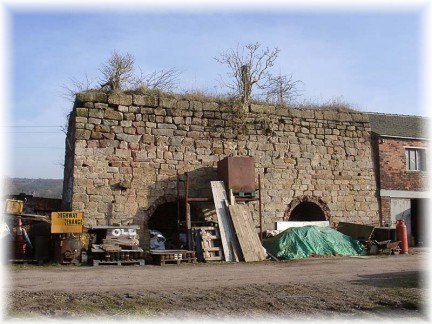

The track exited the tunnel on a high embankment, and then the contents were

poured into the kilns below and fired. These kilns were larger than the originals

and were 8-10ft wide. Once the firing was complete the kilns were emptied

into more trucks and transported to the railway sidings. As well as mortar

and lime for farms, lime was also used as a flux for the steel smelting process.

During the mid 1800’s, the lime was transported by a loop line to Robert

Heaths steel works in Biddulph.

Falls coal pit on the Staffordshire side of the hill provided the slack that

would keep the limekilns burning. A small network horse drawn railway transported

the coal. This would be similar too, and would pass over the embankment of

the old Stonetrough to Congleton line, this is not marked on the map, and

however after a closer examination of the area, you can quite easily see a

curved embankment by the gravel pits. This coal line came through a cutting

from the Gillow Heath side of Biddulph and was then tipped into waiting trucks,

hence the high embankment. These trucks then followed a rail track down to

the lime works.

Down the deepest Airshaft

In the early part of the 20th century the area around the lime works was leased to Danny Boulton, however Danny was unable to make thempay, and like so many other quarries and mines in the 1920’s was closed down. The quarry was kept well drained, but eventually the overflow got blocked and the quarry has since filled with water.

Years before a coal wharf next to Black Cob had a steam powered aerial ropeway to transport its coal.

Danny Boulton re-routed this ropeway

and was able to transport the ganister in this more efficient method. Speaking

to a local farmer who remembers the ropeway, I have learnt that it was 30ft

high. The course of this ropeway can be seen on the map. A 100hp-oil engine

replaced the steam engine, this powered the ropeway, and the compressors used

to turn the mortar mill that powdered the ganister. Eventually roads were

once again to provide the means of transport and a hopper can clearly be seen

from the road.

Also on the map at Baytree Farm you will notice a building running horizontal

to the road, and a small track leading to it. This was the brick works. This

lower field had a layer of clay as well as sand, both of which were put to

good use. Again this has long since gone, and the field has been landscaped

back to normal use.

The Last remaining Lime Kiln (Astbury Sidings)

Picture courtesy David Kitching ©